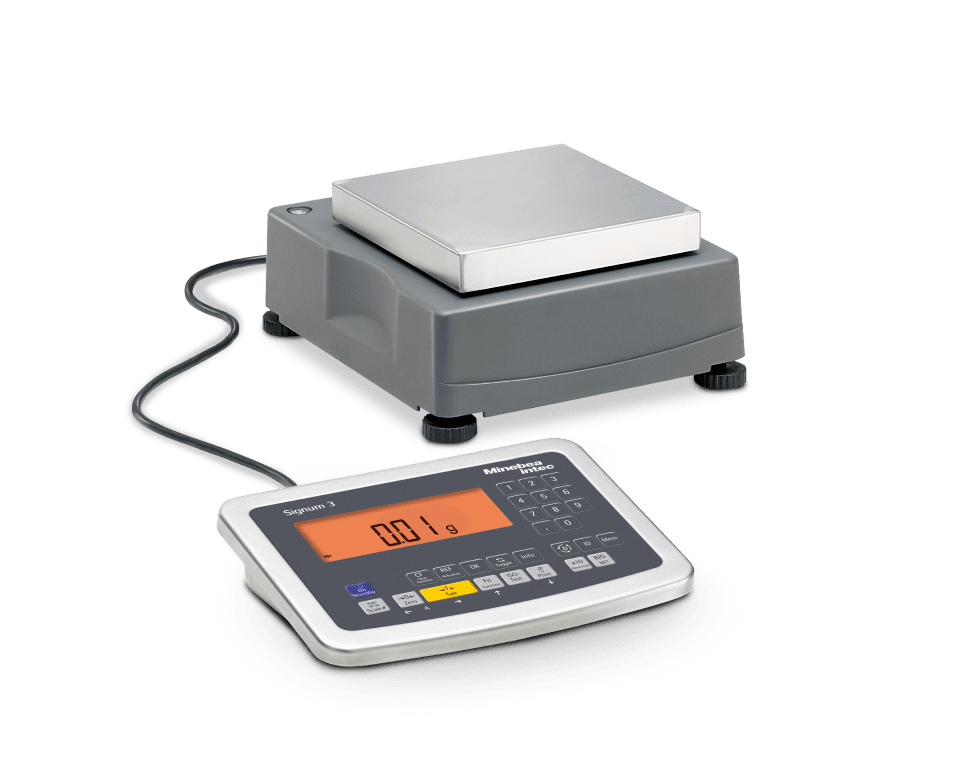

Signum® Industrial Scales

The bench scale Signum® has been specifically developed as a compact solution for a variety of industries. All scales in the range are based on strain-gauge (SG) or electromagnetic force compensation (EMFC) technology. Within everyday weighing applications, they stand out thanks to their short measurement times, flexibility and safety.

The bench scale Signum® has been specifically developed as a compact solution for a variety of industries. All scales in the range are based on strain-gauge (SG) or electromagnetic force compensation (EMFC) technology. Within everyday weighing applications, they stand out thanks to their short measurement times, flexibility and safety.

- three easy-to-use indicators with varying usage levels

- IP43 or IP65 protection classes

- a variety of finishes, e.g. stainless steel

- load ranges of between 0.6 kg and 65 kg

- readability from 0.001 g to 10 g

- platforms in various designs and sizes

- verification mode and explosion-proof solutions

- a wide range of interfaces

- an extensive range of accessories, options and add-ons

The indicator can be set up according to the use regardless of location of the platform and can even be mounted on a stand. Our customers can choose between models with Supreme, Advanced or Regular specifications, depending on the level of precision required. The Signum® industrial scale from Minebea Intec is a compact industrial scale in which a choice of two powerful technologies is used: SIWR and SIWA models work with a strain-gauge type load cell; the high-resolution SIWS models feature monolithic weigh cells based on electromagnetic force compensation. The Signum® offers exceptional performance features and, despite its wide variety of functions, is a very easy-to-operate industrial scale. The Signum® is extremely rugged and resistant, and perfectly adapts to any ambient conditions in an industrial environment.

Particularly suited for uses such as:

- automatic and manual dosing and filling

- manual dispensing, production of mixtures

- totalling and picking of orders

- classing, classification and sorting by weight

- part counts for materials management

- simple recording of weights with logs for documentation

- checking, for example when checking contents of pre-packaged units

- weighing containers and vessels for storage management